The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Shrink Bundlers / Multipackers

nVenia’s shrink bundlers and print-registered multipackers — designed for trays, pads and film-only applications — are used in a wide range of industries. These include food and beverage, household products, pharmaceuticals, automotive, construction materials and hardware.

Arpac Brand 25TW Model Tray Wrapper

Our Arpac Brand 25TW Model tray wrapper is part of a dependable line of shrink packaging systems designed to service a wide variety of industries with around-the-clock reliability.

Arpac Brand 45TW Model Tray Wrapper

Our Arpac Brand 45TW Model tray wrapper is part of a dependable line of shrink packaging systems designed to service a wide variety of industries with around-the-clock reliability.

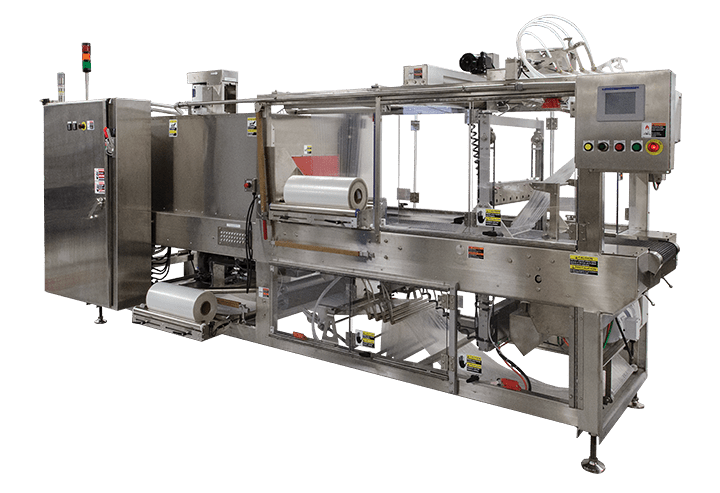

Arpac Brand BPTW Model Shrink Bundling Multipacker

Our Arpac Brand BPTW Model is the champion in shrink bundling equipment for the medium to high volume food and beverage industry. This versatile continuous motion bottom overlap shrink wrapping system operates on demand, without a seal bar to shrink wrap up to 70 trays per minute.

Arpac Brand BPMP Model Shrink Bundling Multipacker

Our Arpac Brand BPMP Model is the champion in multi-packing equipment for the medium to high volume food and beverage industry – shrink wrapping up to 65 unsupported multi-packs per minute.

Arpac Brand BPSW Model Shrink Bundling Multipacker

Our Arpac Brand BPSW Model is a continuous motion, high-speed, bottom overlap film wrapping system specifically designed for the roofing shingle industry.

Arpac Brand BPTS Model Shrink Bundling Multipacker

Our Arpac Brand BPTS Model is a continuous motion, inline, combination shrink wrapping machine designed to serve a wide range of industries.

Arpac Brand AGR Model Shrink Bundler

Our Arpac Brand AGR Model is a compact, right-angle infeed shrink bundling system specifically designed and built for the dairy and frozen food industry.

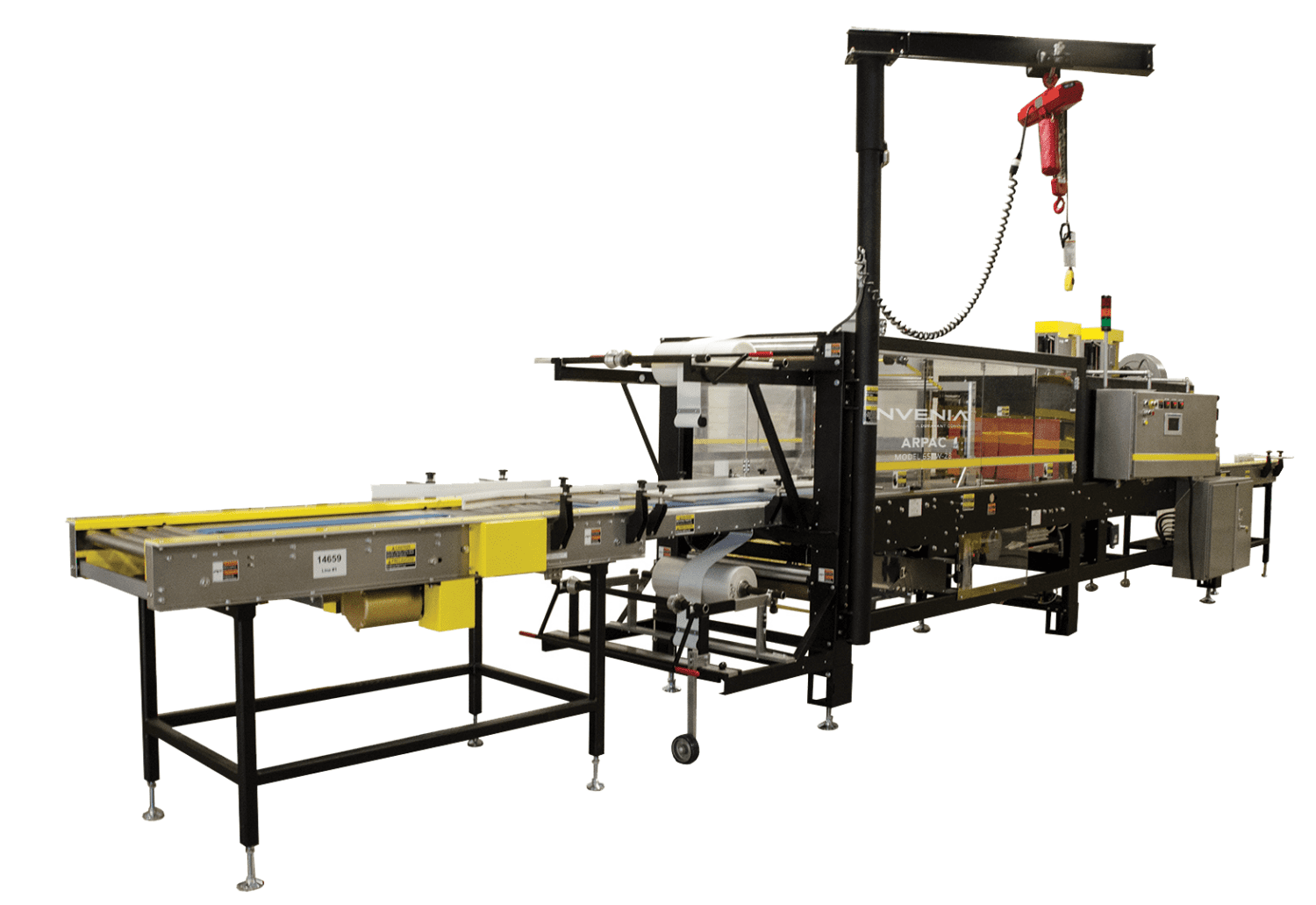

Arpac Brand 105/125 Series Shrink Bundlers

Our Arpac Brand 105/125 Series shrink bundlers are designed to handle doors, windows, and other stacks of large products with either a bullseye enclosure or a fully enclosed shrink package.

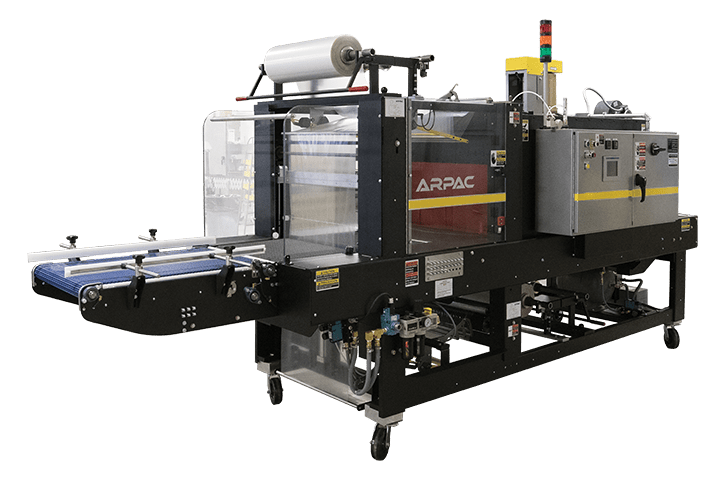

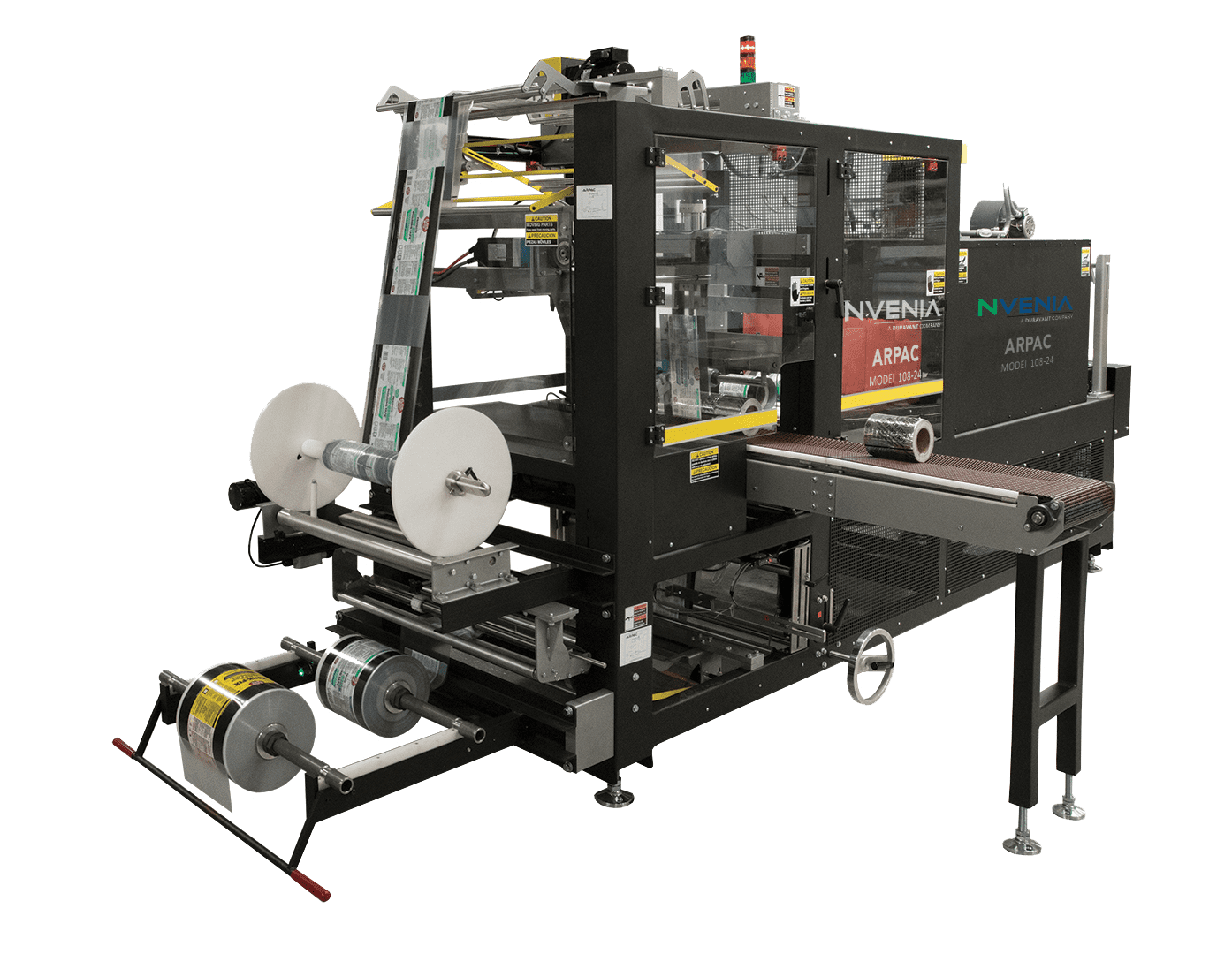

Arpac Brand 108 Model Shrink Bundler

Our Arpac Brand 108 model is an intermittent motion shrink bundler designed to be a rugged and durable system for around the clock operation in almost any type of product environment.

Arpac Brand 708HB Model Shrink Bundler

Our Arpac Brand 708HB Model is a right-angle, intermittent motion shrink bundler designed specifically for today’s pharmaceutical, health and beauty industries.

Arpac Brand 75LTW Model Tray Wrapper

Our Arpac Brand 75LTW Model is a continuous motion tray wrapper capable of wrapping up to 75 trays per minute, depending upon product size.

Arpac Brand 65TW Model Tray Wrapper

Our Arpac Brand 65TW Model is a continuous motion bundler capable of wrapping up to 65 trays per minute, depending upon product size. It’s rugged design ensures years of reliable service.