The Duravant family of operating companies serve the food processing, packaging and material handling segments.

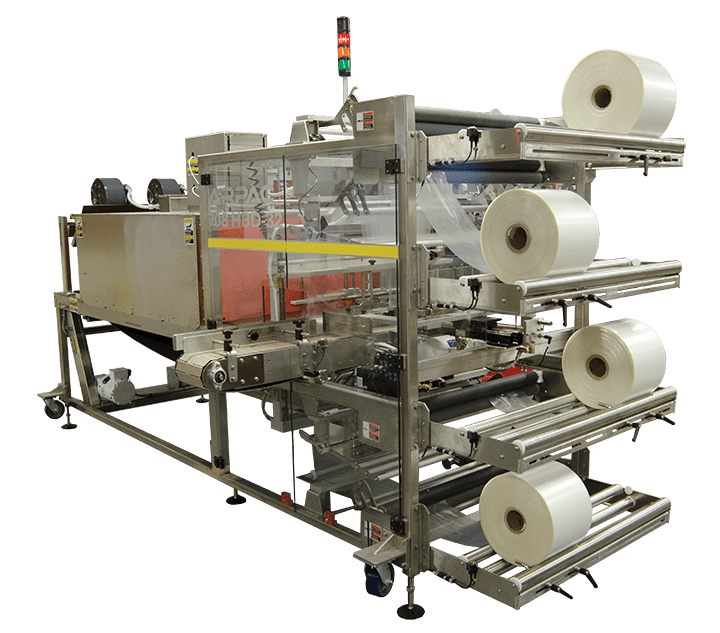

Arpac Brand 708HB Model Shrink Bundler

Our Arpac Brand 708HB Model is a right-angle, intermittent motion shrink bundler designed specifically for today’s pharmaceutical, health and beauty industries.

Ultra-compact in design and economical in price, the 709HB Model is capable of shrink wrapping up to 20 bundles per minute in a single lane configuration. This model uses motorized pulleys rather than separate drives an chain,. This allows for clean, safe operation and a slim machine frame.

Are you interested in this product?

We are here to help.

Features

Standard

- Compact single-frame stainless steel construction

- Heavy-duty system for 24/7 operation

- Simple setup and tool-less changeovers for ease of use and minimal downtime

- Low maintenance conveyor belts do not require tracking adjustments

- Motorized pulleys eliminate chain drives and operate more cleanly, with reduced maintenance cost and less noise

- Quick-change seal bar with military-type quick disconnect

- Top and bottom film racks accommodate four 14″ diameter rolls of film

- No lubrication required for clean and easy maintenance

Options

- Turbo cooling for quick product handling after shrink tunnel

- Servo driven main ram

- Standard or custom infeeds

Standard Specs

Standard Specs

Speed

Up to 20 packages per minute

Electrical Power Requirements

208, 230 or 460VAC, 3 Ph, 60 Hz

Compressed Air Requirements

8 SCFM @80 psi

Product Range

- Minimum: 3/4″ W x 3/4″ x 1/2″ H

- Maximum: 6″ W x 11″ L x 8″ H

Film Roll Diameter

14” maximum with 3″ core

Film Gauge

3 mil.

Film Type

Low density polyethylene, clear or randomly printed