The Duravant family of operating companies serve the food processing, packaging and material handling segments.

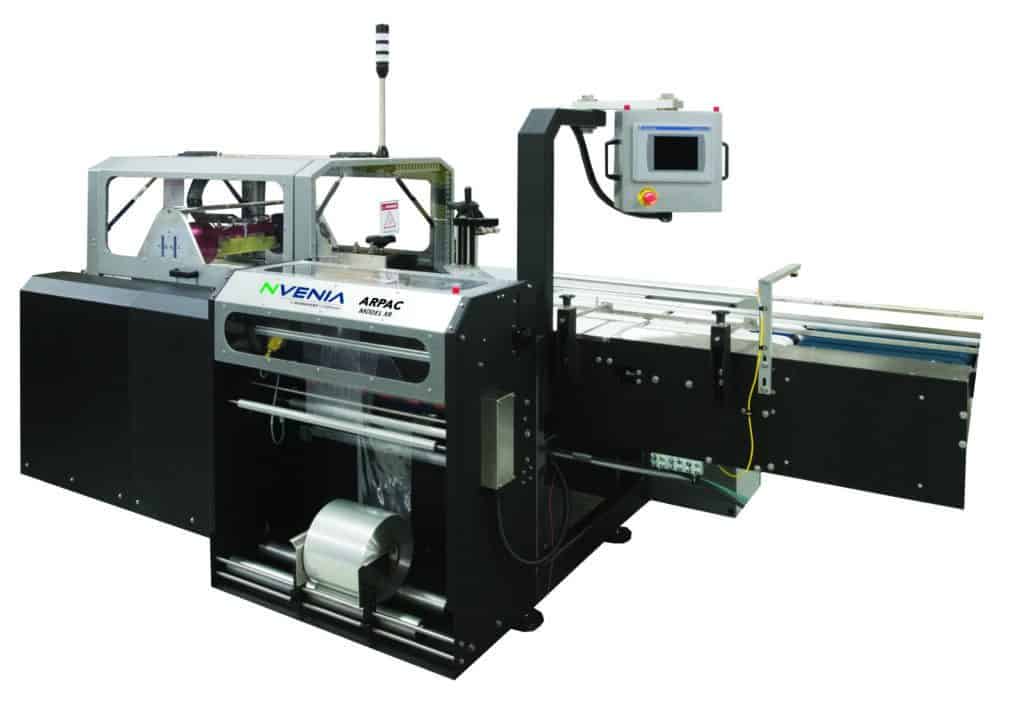

ARPAC Brand XR Series Shrink Wrappers

Our Arpac Brand XR Series represents our high performance wrapper, ideal for high speed applications that require accurate and repeatable shrink seal quality.

This 4-axis servo driven XR wrapper provides real-time feedback and control to run precisely spaced products regardless of changes in the incoming product speed. With our patented rotary head design, the XR model is a robust, high performance design that focuses on machine uptime and reliability. The XR series can be configured in a typical cross seal or top seal orientation to fit a wide range of product profiles.

Are you interested in this product?

We are here to help.

Features

Standard

- Patented rotary cross seal motion for smooth high speed performance – rotary top seal optional

- 4 Servo axis for high speed accuracy and repeatability

- Speed modulation programming will match upstream production rates for smooth product control

- Low height film rack holds double length centerfolded rolls of film

- Heavy duty welded construction

- Powder coat finish provides a durable scratch resistant surface that prevents corrosion

- Power selvage winder with dancer bar control & film break detect

- NextGen Side Seal/Top Seal with overload & wrap around sensor

- Electronic film bunching relieves film tension between products

- Tool-free changeover

- Direct drives for maintenance free operation

- All conveyor drives servo driven for maximum control and precision

Options

- Standard or custom infeeds for almost any application

- Powered product bypass

- Single or dual roll film centerfolders

- Rotary top seal

Film

- 45-90 gauge polyolefin

- 1-3 mil low density polyethylene

- Film width up to 64″ flat or 30″ centerfolded

Standard Specs

Standard Specs

Speed

Up to 200 cycles per minute

Electrical Power Requirements

460 VAC, 3 Ph, 60 Hz

Compressed Air Requirements

None

Product Dimensions

XR-15: 14″W x Infinite length x 4.5″ H

XR-24: 22″ W x Infinite length x 4.5″ H

XR-30: 30″ W x Infinite length x 4.5″ H

Top Seal Model: 5″ W x Infinite length x 10″ H

Film Roll Diameter

16”

Film Type

- 40-90 gauge polyolefin

- 1-3 mil LDPE

- File width up to 64″ flat or 30″ centerfolded