The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Arpac Brand VT Model Shrink Tunnel

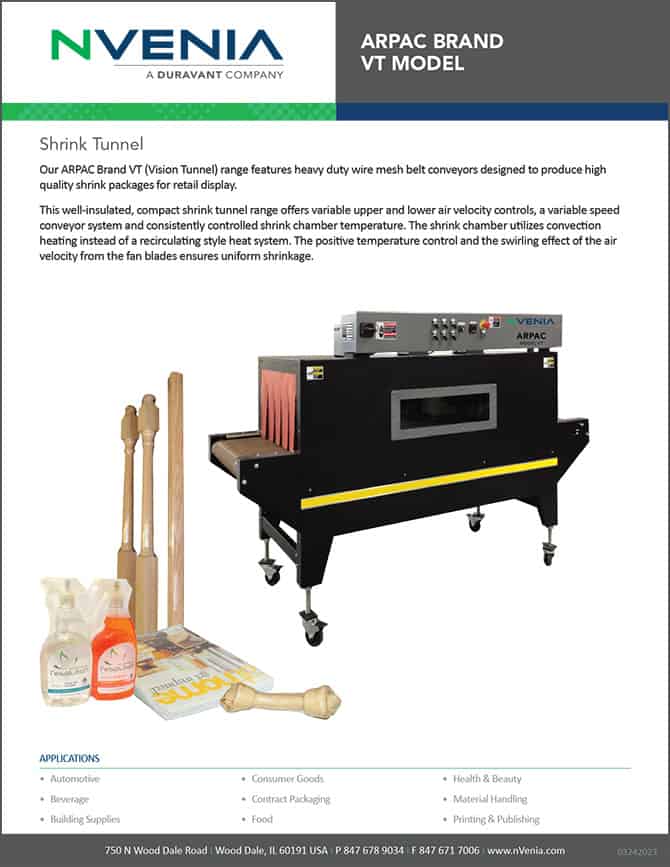

Our Arpac Brand VT (Vision Tunnel) range features heavy duty wire mesh belt conveyors designed to produce high quality shrink packages for retail display.

This well-insulated, compact shrink tunnel range offers variable upper and lower air velocity controls, a variable speed conveyor system and consistently controlled shrink chamber temperature. The shrink chamber utilizes convection heating instead of a recirculating style heat system. The positive temperature control and the swirling effect of the air velocity from the fan blades ensures uniform shrinkage.

Are you interested in this product?

We are here to help.

Features

Standard

- Compact welded steel frame with laser cut components

- Powder coat finish provides a durable scratch resistant surface that prevents corrosion

- Operator side viewing window with illuminated shrink chamber

- Double insulated shrink chamber offers maximum energy efficiency with minimal heat loss

- Convection style heating system provides consistent shrink wrapping

- Variable upper and lower air velocity controls

- Top and bottom Calrod heating elements

- Variable speed conveyor provides flexibility with uniform shrinkage

- Standard heavy duty wire mesh belt

- Standard casters mounted with leveling legs for machine portability

Options

- Standard and custom belts available

- Air motor for tunnel evacuation in the event power loss

- Internal product guides prevent fall-through and jams

- UL certified electrical cabinet

- 480VAC, 3Ph, 60Hz power

Standard Specs

Standard Specs

Speed

Conveyor speed up to 180 feet per minute

Electrical Power Requirements

VT18: 230VAC, 3Ph, 60 Hz 32 A

VT18-EXT: 230VAC, 3Ph, 60 Hz 67A

Chamber Size

VT18 Model

- 12.5″ H x 21.5″ W x 72″ L

- Conveyor width: 20″

VT18-EXT Model

- 12.5″ H x 21.5″ W x 96″ L (Total Length of 96″)

- Conveyor width: 20″

Max Product Height

10″

Shipping Weight

VT18: ~750 lb

VT18-EXT: ~1,000 lb