The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Arpac Brand TrayStar Model Tray Packer

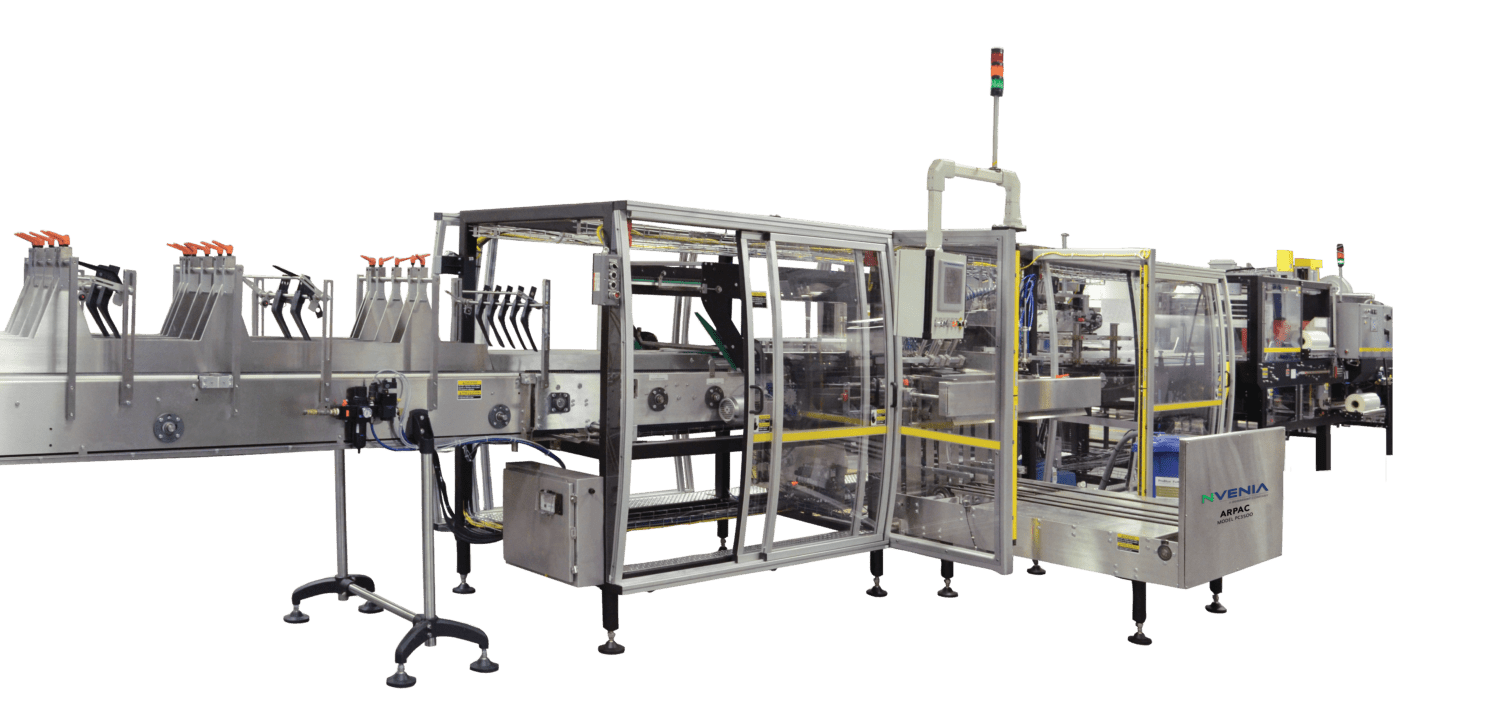

Our Arpac Brand TrayStar Model high-speed, continuous motion tray packer makes automatic tray loading a variety of products, such as bottles, cans, cartons, jars, fast and easy.

The TrayStar tray packer automatically loads product into a wraparound tray at speeds of up to 60 trays per minute. Wraparound trays ensure that the product is enclosed in a tightly fit tray, preventing scuffing and product damage. The machine features gentle product handling and loading to keep your product looking pristine.

Our rapid changeover design with color-coded lane spacing guides, user-friendly touchscreen controls, and servo controlled collators, allows line operators to switch to a different product size quickly and efficiently.

Are you interested in this product?

We are here to help.

Features

Standard

- Simple machine adjustments and quick change capabilities for fast product changeovers

- Heavy-duty rugged construction designed for durability and 24/7 operation

- Nordson ProBlue® hot melt glue unit for superior application flexibility and adhesion

- Rolling canopy guarding provides safe, easy access to the machines interior

- Gentle product handling throughout System for Maximum Product Protection

- Easy Interface Adjustments allow for Simple Operator Control

Options

- Extended Blank Magazine

- Standard or Custom Product Collation

- Automatic Lane Divider

- Extended Infeeds

Corrugate

- B or C flute corrugation

- Burst strength: 150 or 200 lb. per square inch

- Balanced outside and inside liners to avert warped blanks

- Minimum combined weight facings: 98 lb. per square inch

Standard Specs

Standard Specs

Speed

Up to 60 trays per minute

Electrical Power Requirements

240 or 480VAC, 3Ph, 60Hz

Compressed Air Requirements

80 psi, 20 CFM

Product Height

2″ – 10″

Tray Dimensions

- Minimum Tray Size: 7″ W x 9″ L x 1.5″ H inches

- Maximum Tray Size: 18″ W x 23″ L x 4″ H inches

Tray Wall Height

1.5” – 4”

Blank Dimensions

- Minimum Flat Tray Blank Size: 11″ W x 9″ L

- Maximum Flat Tray Blank Size: 25″ W x 24″ L