The Duravant family of operating companies serve the food processing, packaging and material handling segments.

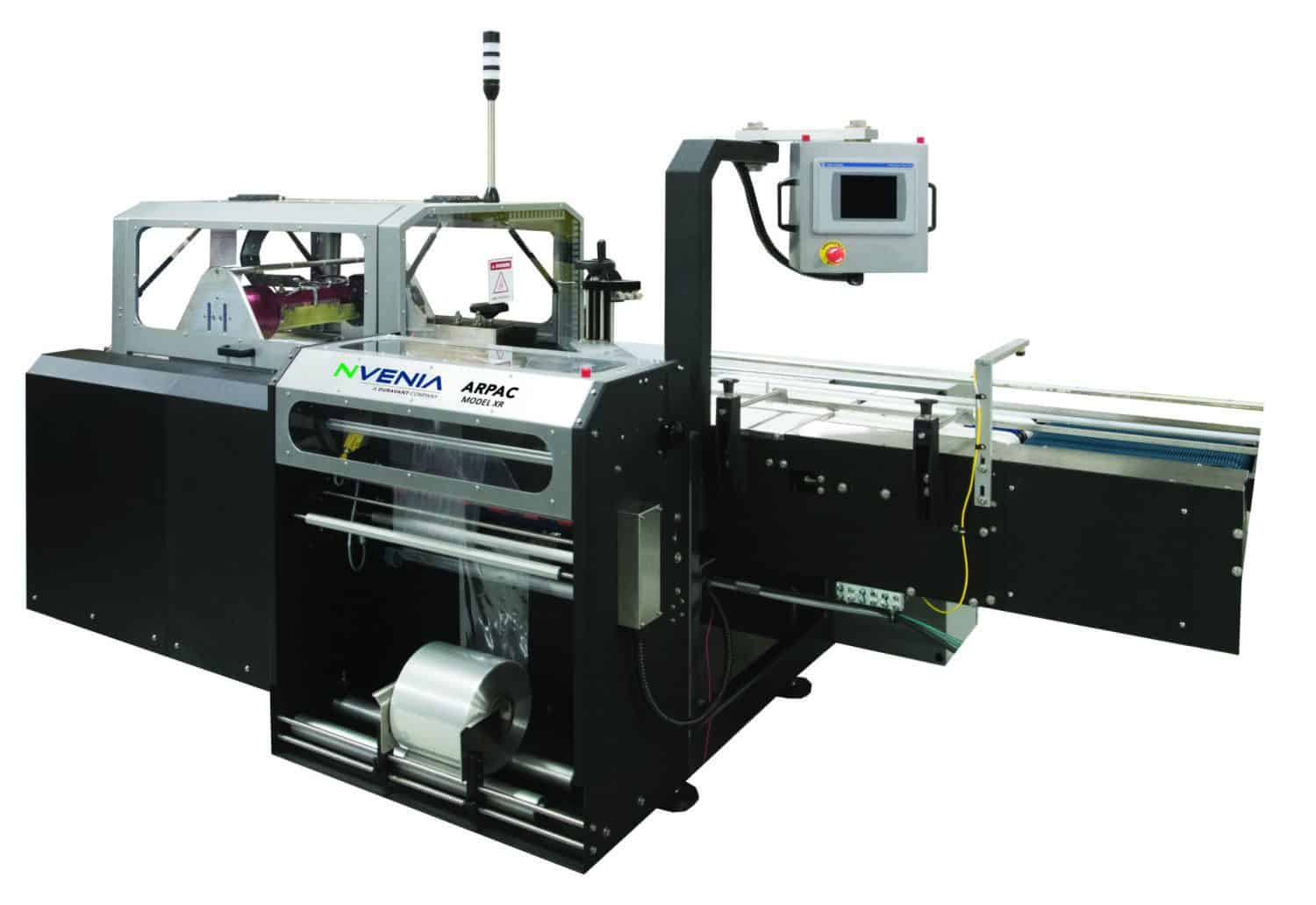

ARPAC Brand S Series Shrink Wrappers

Our Arpac Brand S Series models are servo driven, continuous motion shrink wrappers that excel in a wide variety of applications. The S is designed to increase productivity, reduce wear and tear on parts, and eliminate wasted time and energy. We accomplish this by using a continuous motion design with smooth, fast, and unbroken flow. With its superior design, the S is more reliable, requires less maintenance, uses less film and energy, and provides superior film tension for a better, more consistent package. The S Series is available in a traditional cross seal or a top seal orientation to accommodate a wide range of products at up to 120 packages per minute.

Are you interested in this product?

We are here to help.

Features

Standard

- Dual axis servo driven cross seal and seal carriage

- Next Gen Side Seal with overload and wrap sensor technology – Top Seal optional

- Electronic film bunching at cross seal relieves film tension between products resulting in consistently stronger seals

- Low height film rack holds double length centerfolded rolls of film up to 16” diameter

- Side mounted film cradle for easy film load access

- Heavy duty welded construction

- Powder coat finish provides a durable scratch resistant surface that prevents corrosion

- Tool free adjustable film former

- Powered selvage winder with dancer bar control and film break detection

- Electronic jam protection at cross seal

- Multi-zone seal bar for even heat distribution

- Inclinometers at film unwind and selvage winder replaces potentiometers

- Direct driven conveyor sections eliminates maintenance

Options

- Standard or custom infeeds for almost any application

- Light stack with 3 lights & alarm

- Low film alert to warn operator when film is low

- No film alert with programmed machine stop

- Servo driven conveyor sections

- UL electrical panel certification

- Clustered lube station manifold for quick and easy maintenance

- Powered product bypass

- Single or dual roll film centerfolders

- External film stand for flat film

Standard Specs

Standard Specs

Speed

Up to 150 feet per minute or 120 packages per minute

Electrical Power Requirements

240/480 VAC, 3 Ph, 60 Hz

Compressed Air Requirements

No air required

Product Dimensions

S18: 18″ W x Infinite length x 8″ H

S24: 24″ W x Infinite length x 12″ H

S30: 30″ W x Infinite length x 12″ H

TS: 2″-20″W x 2″-Infinite length x 0.25″-25″ H

Film Roll Diameter

Film Gauge and Type

- 40-90 mil polyolefin (cross seal), 30-150 mil (top seal)

- 1-4 mil low density polyethylene

- PVC and other film blends capable

- Film width up to 78″ flat or 38″ centerfolded

Other Film Specifications

Up to 38″ centerfolded