The Duravant family of operating companies serve the food processing, packaging and material handling segments.

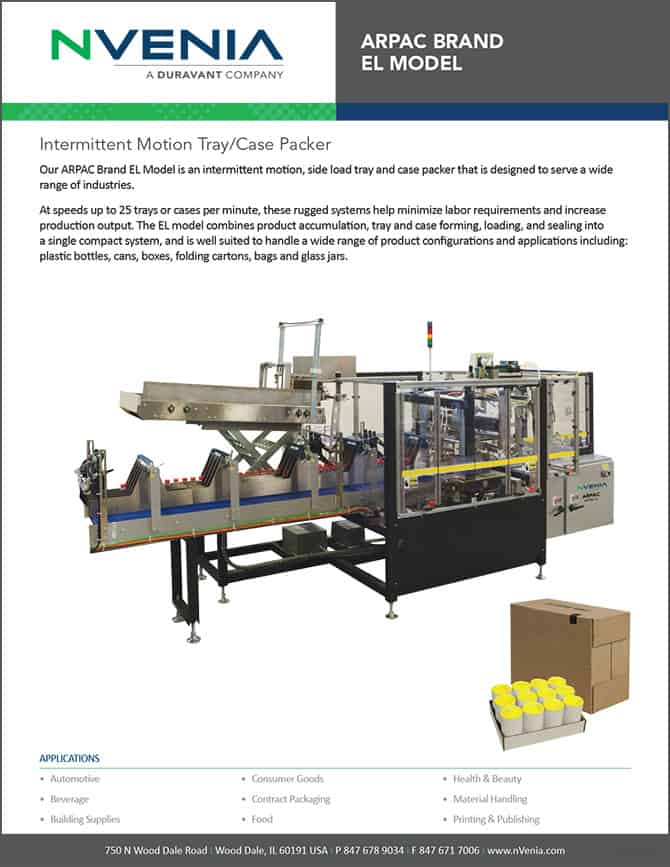

Arpac Brand EL Model Case and Tray Packer

Our Arpac Brand EL Model is an intermittent motion, side load tray and case packer that is designed to serve a wide range of industries.

At speeds up to 25 trays or cases per minute, these rugged systems help minimize labor requirements and increase production output. The EL model combines product accumulation, tray and case forming, loading, and sealing into a single compact system, and is well suited to handle a wide range of product configurations and applications including: plastic bottles, cans, boxes, folding cartons, bags and glass jars.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty rugged construction designed for high durability and 24/7 operation

- Durable powder coated finish for long life

- Allen-Bradley® programmable logic controller

- Rapid changeovers with crank adjustable dials

- Vacuum blank feed handles variation in corrugated board and can be resupplied while machine is in operation

- Durable Intralox conveyor belts eliminate tracking problems

- Nordson ProBlue® hot melt adhesive system for superior application flexibility and adhesion

- Central point lubrication simplifies preventive maintenance

Options

- Servo driven indexing and compression

- Crank adjustable lane guides

- Complete automatic changeover with pushbutton control

- Extended blank feed

- Custom product collation

- Left or right hand operation

- Left or right hand 90º infeed

Corrugate

- B or C flute corrugation

- Burst strength: 150 or 200 lb. per square inch

- Balanced outside and inside liners to avert warped blanks

- Minimum combined weight facings: 98 lb. per square inch

- Maximum 1/4″ warpage over 12″ corrugate surface

Glue Type

- Food grade hot melt adhesive

- Transparent, odorless, granulated

- 0.5 – 1 second set time

- Ejected at 300º to 350ºF (160º to 180º C)

Standard Specs

Standard Specs

Speed

Up to 20 trays or cases per minute

Electrical Power Requirements

460VAC, 3 Ph, 60 Hz

Compressed Air Requirements

80 psi

Product Dimensions

- Minimum product size: 7″ W x 5.5″ L x 3″ H

- Maximum product size: 21″W x 15″ L x 8″ H

Blank Dimensions

- Maximum blank size: 30” across machine direction x 25” in machine direction

- Minimum blank size: 9.75” across machine direction x 7” in machine direction

Tray Wall Height

1.5” – 3.75″

Higher wall optional