The Duravant family of operating companies serve the food processing, packaging and material handling segments.

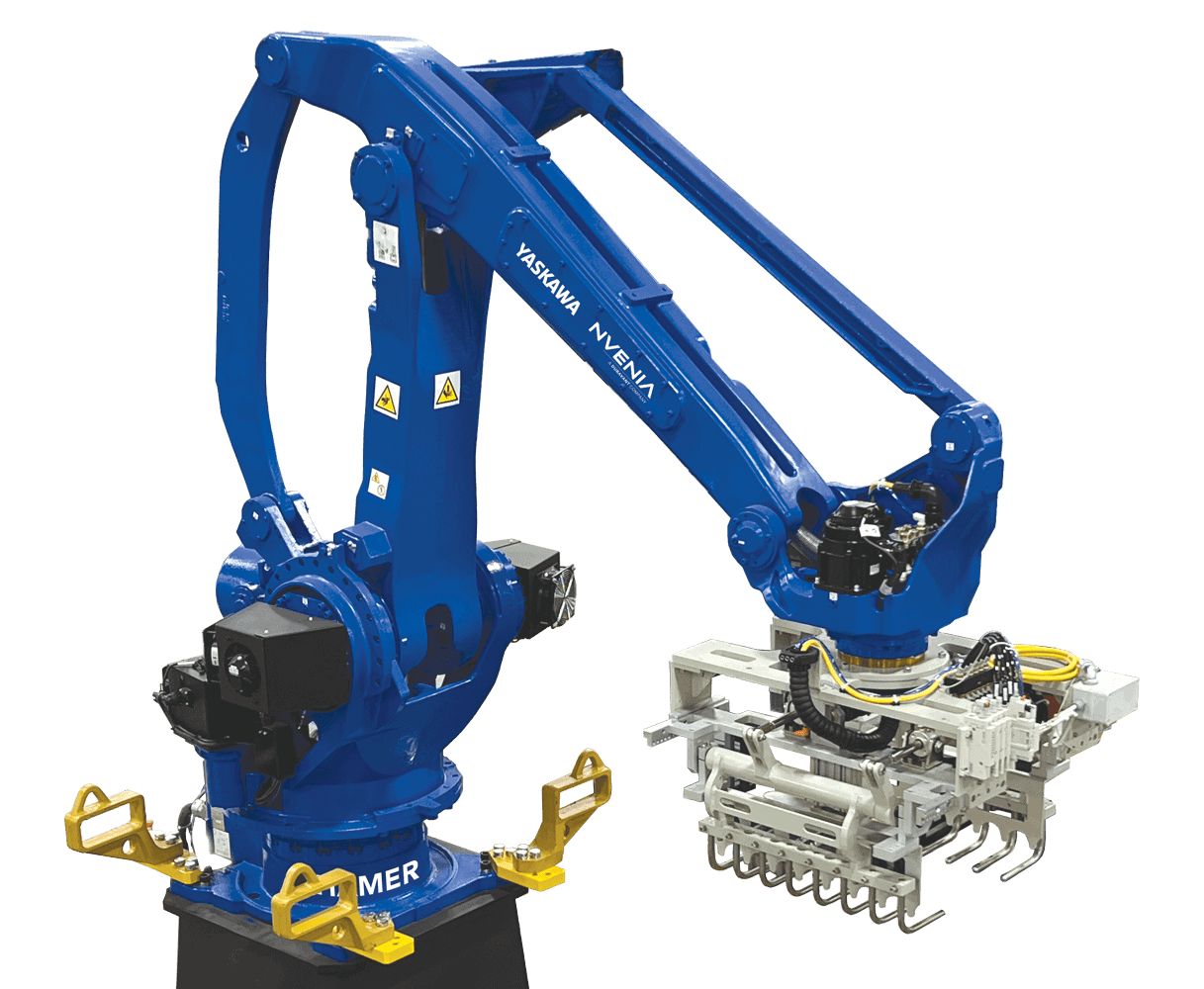

Arpac Brand Robotic Palletizer Model

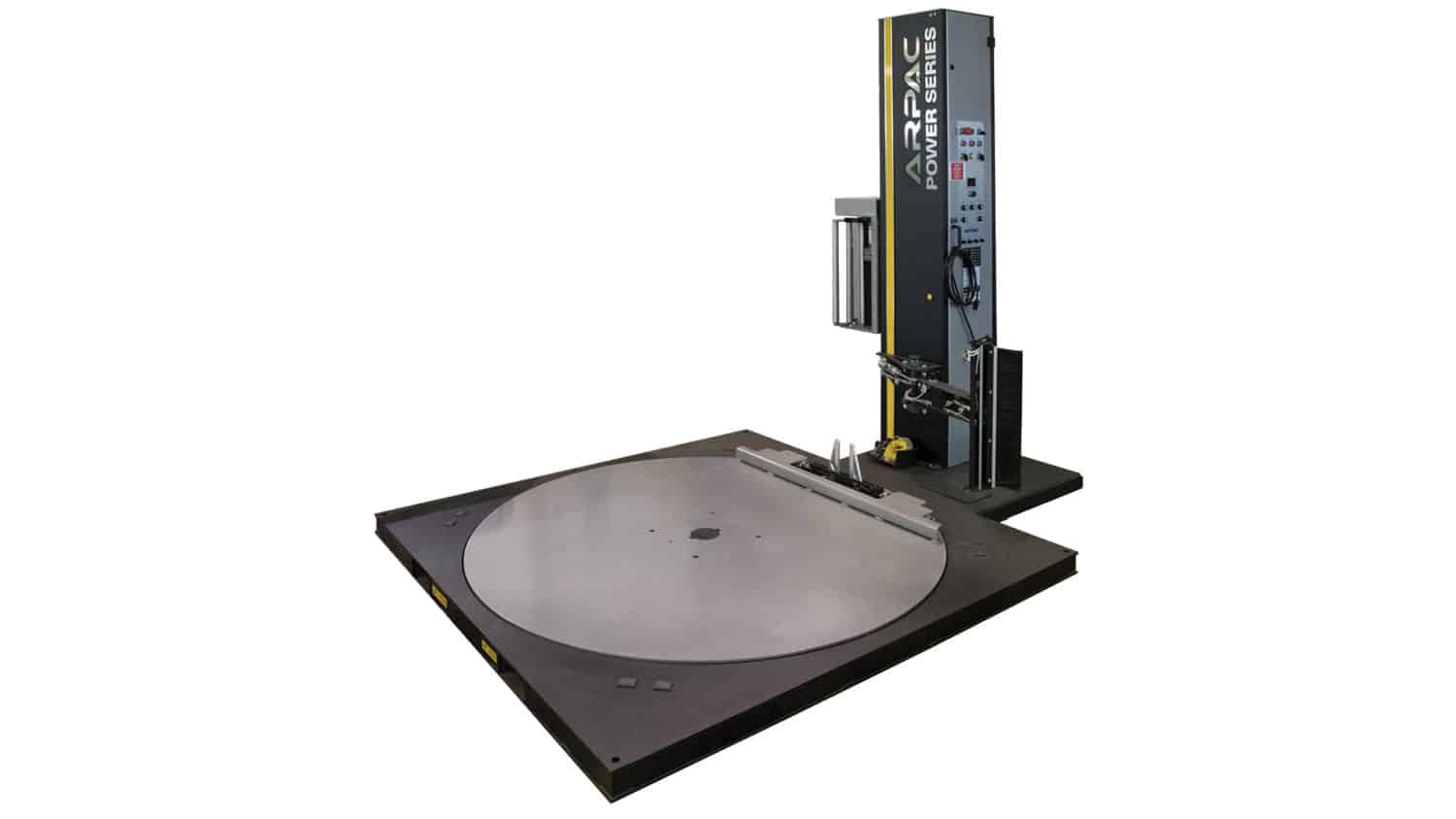

Our Arpac Brand Robotic Palletizer Model is a pre-engineered robotic palletizing cell that automatically stacks and wraps pallets to exact specifications. It consists of a multi-axis robot, end of arm tool, automatic stretch wrapper, pallet dispenser and conveyance system within a space efficient footprint. Palletizer cells range from a one-line in/one-line out configuration, up to a four-line in/four-line out configuration to match your application needs.

End of Arm Tools (grippers) are matched to the application and range from simple suction cups and vacuum plates, to fork and bag style tools. Custom tool designs are also available to accommodate virtually any product.

The system can accommodate cases, trays, bundles, bags, etc. Speeds vary by application; however, rates up to 60 pieces per minute are possible. An automatic pallet dispenser supplies pallets as needed and can be reloaded while the system is running to maximize efficiency. Slip sheets and tier sheets can also be placed as needed. After the load is complete, it is transferred to a fully automatic stretch wrapping station, allowing the robot to immediately begin building the next pallet. Wrapped pallets are then discharged to a staging conveyor for pick-up. For operator safety, a fully interlocked guard system is provided that immediately stops the robot in the event that a perimeter door is opened. Robotic palletizing systems offer consistent, predictable production; usually at higher rates than their human counterparts. They improve quality, minimize rework, and can operate 24/7 – while handling heavy/bulky products and preventing injuries.

Are you interested in this product?

We are here to help.

Features

Standard:

- 5-Axis 80kg (176lb) palletizing robot accommodates products up to approximately 100 lbs

- Dedicated robot controller

- A variety of gripper options for all types of packages

- 10’ infeed conveyor with pneumatic product separation

- Automatic pallet dispenser, with 10 pallet magazine and drag chain discharge conveyor

- 60” pallet build station conveyor

- Integrated conveyorized turntable stretch wrapper up to 45 loads/hour

- 60” pallet discharge conveyor

- Allen-Bradley® CompactLogix™ PLC

- PanelView™ Plus 1000 – 10 inch color HMI

- Heavy duty construction with powder-coated finish

Options:

- 80kg, 100 kg, 160 kg, 190 kg, 300 kg, 500 kg or 800 kg 4 & 5 axis robots

- Vacuum plate, fork style or bag style end of arm tool

(custom designs also available) - Layer sheets – gripper tooling and manually

loaded sheet rack - “Smart” counting style gated infeed conveyor

(supports multiple products with no changeover) - 2 in / 2 out configuration

- 3 in / 3 out configuration

- 4 in / 4 out configuration

- Full line system integration

Standard Specs

Standard Specs

Each system is configured to your specific application. Please contact your local nVenia representative to assist you in designing a robotic palletizing system suited to your needs and budget.